Challenge

Klein Kromhof from Daarlerveen is a wood processor and producer of high-quality wood fiber products such as ground cover for stables, but also biofuels in the form of pressed wood pellets. The 40-year-old family business has implemented various innovations in recent decades and has thus become a producer with a worldwide sales market. They have achieved this with the upgrade of the modern machinery and the addition of their own energy production in the form of cogeneration with a capacity of 7.5 megawatts. From tree trunk to end product, the entire process takes place in Daarlerveen.

The production process is completely in-house and largely automated. This is achieved by the large machinery consisting of robots, debarking machines, sawing machines, screening machines, dryers, shredders, shredders and packaging machines.

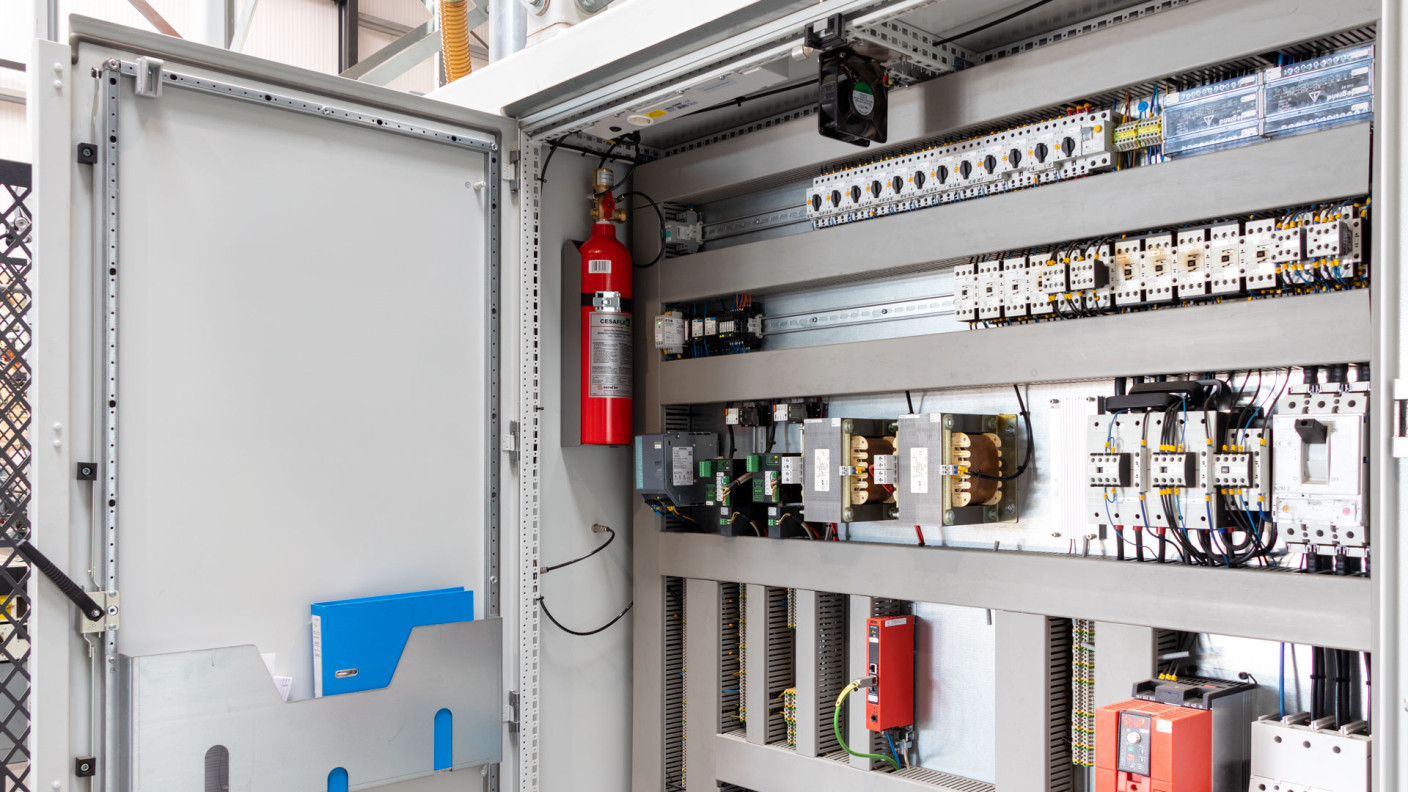

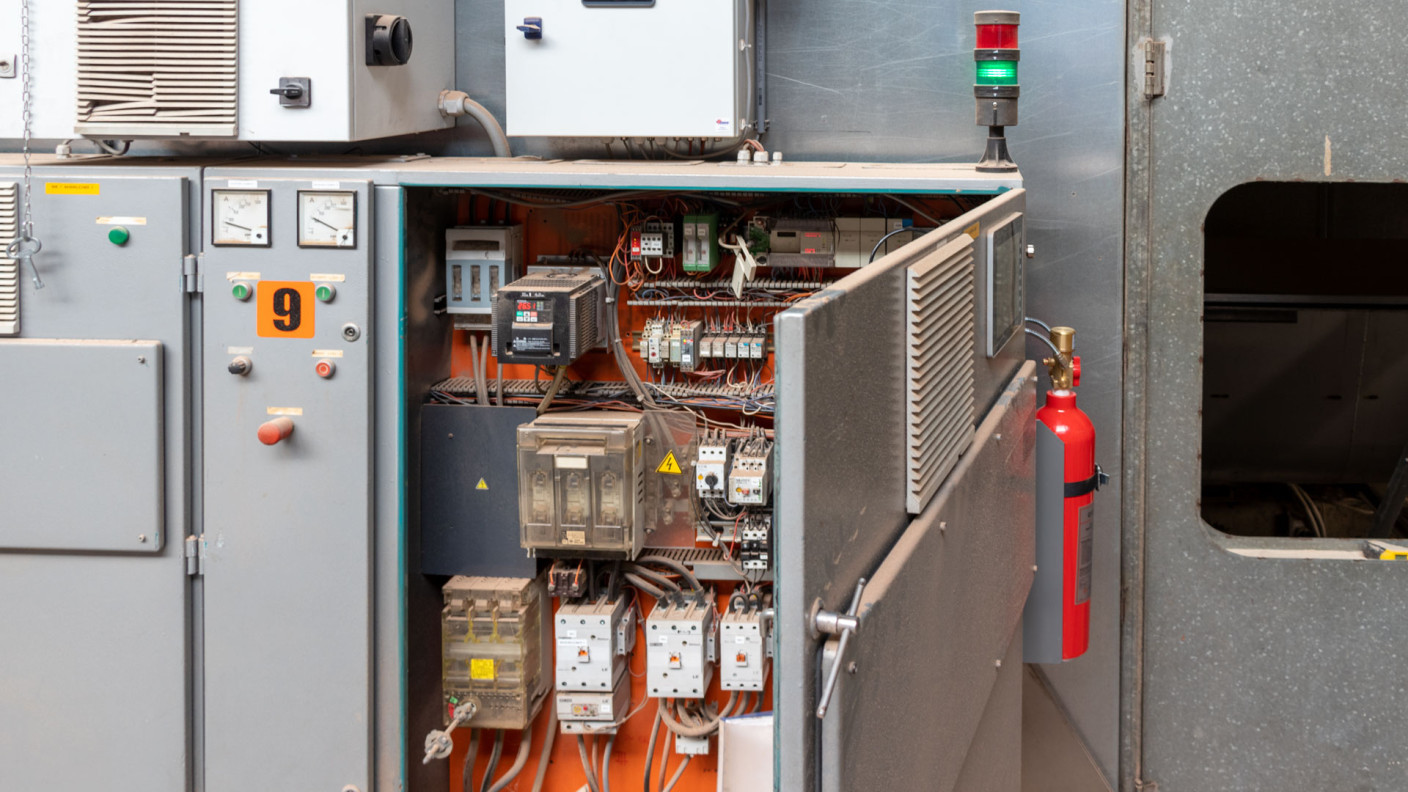

All these machines and processes are controlled by a large number of switch boxes spread over the site in the various halls. Since the environments contain a lot of wood dust and combustible materials, fire protection is of paramount importance at Klein Kromhof.